ERW Steel Pipe(Electric Resistance Welded Pipe), A53 ERW Pipe, ERW Carbon Steel Pipe

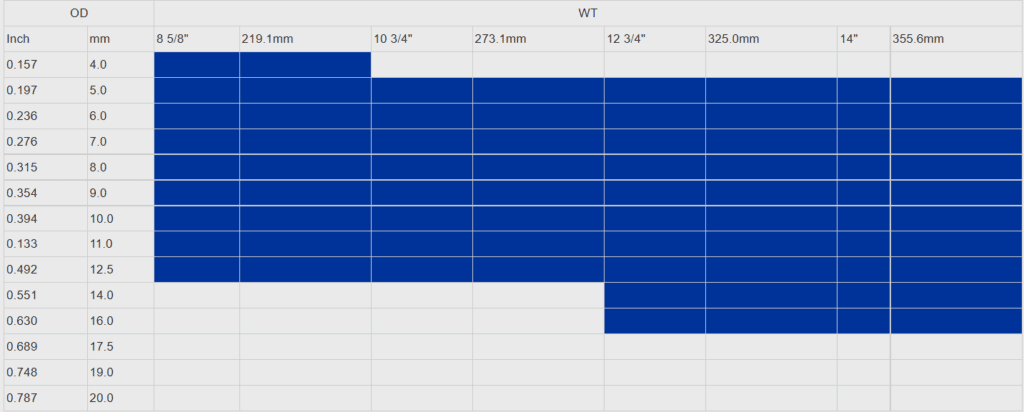

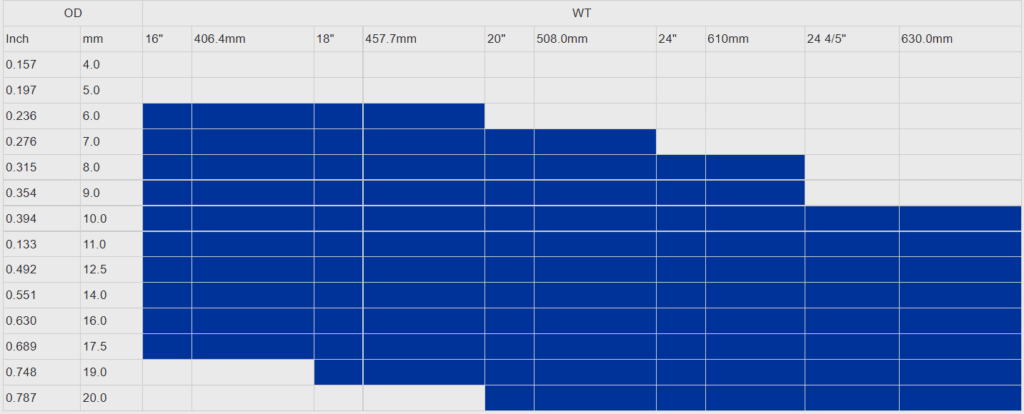

Sizes:

Out Diameter:1/2″-24″

Wall Thickness: 1.65-20mm

Length : 3-12m, or according to customer’s requirement

End : Plain End, Beveled End, Treaded

Standard:

ASTM 5L, ASTM A53, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Steel Grade:

API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

ASTM A53: GR.A, GR.B

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

Uses:

For ERW Line Pipe

For ERW Casing

For ERW Structure Tube

For High pressure and high temperature

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST)

Small diameter erw steel pipe

| Out diameter | Sch 5 | Sch 10 | Sch 40 | ||||

| Inch | mm | Thickness | Kg/mtr | Thickness | Kg/mtr | Thickness | Kg/mtr |

| 1/2″ | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| 3/4″ | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1″ | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 1/4″ | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 1/2″ | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2″ | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 4.81 | 5.31 |

| 3″ | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 1/2″ | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4″ | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5″ | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6″ | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8″ | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

Large diameter erw steel pipe

Large diameter erw steel pipe

ERW Pipe Manufacturering Process:

Straight seam high frequency welded pipe (ERW steel pipe) is formed by forming a hot-rolled coil through a forming machine. The skin effect and proximity effect of high-frequency current are used to heat and melt the edge of the pipe blank. Pressure welding is carried out under the action of a squeeze roller. Realize production. Welded steel pipes have simple production process, high production efficiency, many varieties and specifications, and less equipment, but their general strength is lower than seamless steel pipes.